Aluminum sand casting parts

Basic Info

Model No.: SVI-109

Product Description

Sand Casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. Over 70% of all metal castings are produced via sand casting process.Sand casting is relatively cheap and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding.

Main particulars for Aluminum sand casting parts

|

| MAIN PARTICULARS |

| Tolerance | High accuracy(ISO2768, ISO5817, ISO13920, DIN1690) |

| Material | GS30Mn5,Aluminium, Iron and other material |

| Dimension(L*B*H) | As per drawing, as large as we can |

| Weight | 1KG~15Ton |

| Coating | Sa2.5 blasted and two or three layers painted with highest quality Machined surface with tectyl891 |

| Marking | as per clients' requirements |

| Inspection | material, construction, dimension, non defective test, paint inspection |

| Experience | We have made the pump cover(welded+casted+machined) with big diameter OD3500MM |

| Others | Recyclable, in line with environmental requirements and standards, and reliable |

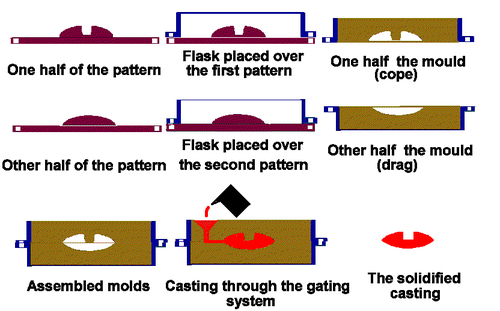

Basic process

There are six steps in this process:

1.Place a pattern in sand to create a mold.

2.Incorporate the pattern and sand in a gating system.

3.Remove the pattern.

4.Fill the mold cavity with molten metal.

5.Allow the metal to cool.

6.Break away the sand mold and remove the casting.

During the molding operation the boxes are located together by pins so that they can be separated to remove the pattern, and replaced in the correct position before the metal is poured in. The boxes are clamped together, or the cope (top section) weighted down when pouring to prevent the cope from `floating away` from the drag (lower section) when the mould is full of molten meta

Sand casting is used to make large parts (typically Iron, but also Bronze, Brass, Aluminum). Molten metal is poured into a mold cavity formed out of sand (natural or synthetic). The processes of sand casting are discussed in this section, include patterns, sprues and runners, design considerations, and casting allowance.

Photos of our Precision aluminum sand casting part

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Casting Parts > Sand Casting Parts