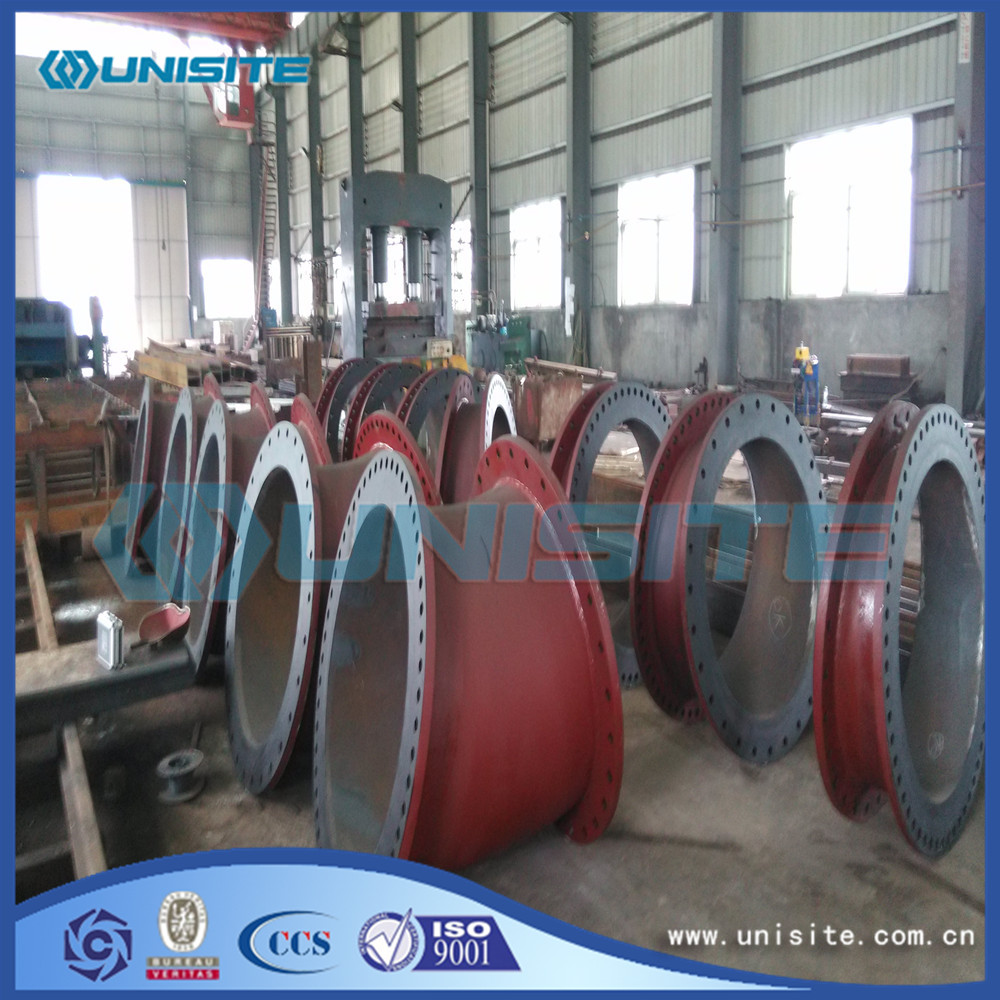

Steel pressed pipe bend fitting

Basic Info

Model No.: USA-079

Product Description

The forming process of Stamping elbow is complicated, and it needs to be welded according to different materials and uses, and is gradually formed under certain pressure. Stamping elbow molding need according to a certain process, strictly comply with the corresponding process, otherwise the production of stamping elbow will produce quality problems.

Material

Stamping elbow material is carbon steel, stainless steel, alloy steel and other materials. Carbon steel stamping elbow is cheap, the use of large. The alloy steel elbow is used in a special position on the.

Stainless steel stamping elbow is different from carbon steel elbow is the main material of different materials, the chemical composition will keep the elbow for a long time will not rust, is not easy to be corroded.

Stainless steel, stainless steel, corrosion resistance as the main characteristics, and the chromium content of at least 10.5%, the maximum carbon content of not more than 1.2% of the steel.

Carbon steel: A234 WPB ASTM/ASME, WPC

Alloy: A234 WP 1-WP 12-WP ASTM/ASME 11-WP 22-WP 5-WP 91-WP911 15Mo3, 15CrMoV, 35CrMoV

Stainless steel: A403 WP 304-304L-304H-304LN-304N ASTM/ASME

A403 WP 316-316L-316H-316LN-316N-316Ti ASTM/ASME

A403 WP 321-321H ASTM/ASME A403 WP 347-347H ASTM/ASME

Low temperature steel: A402 WPL3-WPL ASTM/ASME 6

High performance steel: A860 WPHY 42-46-52-60-65-70 ASTM/ASME

Cast steel, alloy steel, stainless steel, copper, Aluminum Alloy, plastics, PVC, argon Ge Lek, PPR, RFPP (reinforced polypropylene) etc..

The specifications of our bend

High quality pressed bend, with long service life.

Construction

The construction is to be built according to the drawing with rules of good workmanship.

After heating, molding by professional equipment, cutting and heating above the critical temperature; adding quenching agent after some time holding, temperature is reduced suddenly, to meet rapid cooling.

Materials

All fabricated steelwork used in the construction of the bend will be to manufacturing standard of UniSite or other classification society.

All materials proposed will be selected to comply with the latest Health and Safety Rules.

Paint systems for hull protection will be of the highest quality (Hempel, Inter, Sigma, Jotun)

Long-term cooperation with world top dredging and marine companies for more than 10years, UniSite is specialized in providing comprehensive service and parts of dredging, land reclamation, offshore, marine, municipal projects. UniSite is one of the most professional dredging and marine companies in design, manufacture, and construction and related products and services.

UniSite group has a perfect managing system and our staff who are professional in technology are committed, passionate, efficient.

Photos of our Steel Pressed Pipe Bend Fitting

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Pipe Bend > Pressed Bend